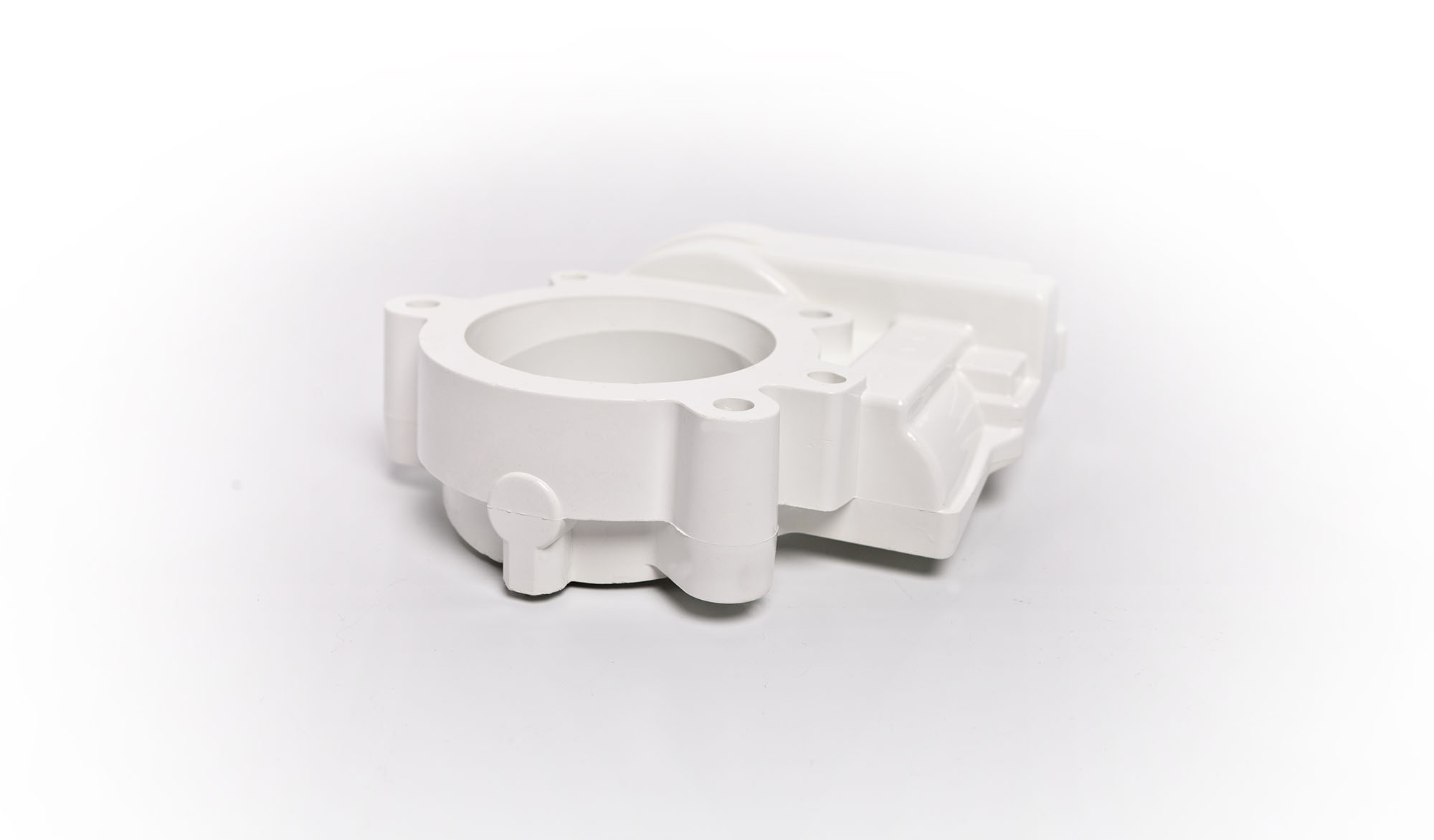

Electrotechnical molded parts

...made of thermosetting molding compounds

Thermosetting materials are particularly suitable for many applications in the electrical industry due to their excellent electrical properties. Other significant advantages include their high flame resistance and electrostatic discharge capability.

In addition to high mechanical strength and stiffness, the molded parts produced by KSM also exhibit exceptional surface hardness while maintaining tight tolerances.

These components are also extremely weather-resistant and are therefore particularly sustainable, allowing us to save resources for our environment.

Thermosetting materials offer:

- Excellent electrical properties

- Electrostatic discharge (explosion protection)

- High flame resistance

- High strength, stiffness, and surface hardness

Thanks to our special tooling techniques and automatic deburring, we can offer you competitive part prices. Feel free to contact us.